- About Problem Solving Products, Inc.

- Services

- ISO 9001:2015 Registered

- Kalrez O-rings, Seals

- Critical Properties

- Compatibility Chart

- Zalak Seals

- Availability of Parts

- Kalrez Industries

- Chemical Process

- Semiconductor

- Ultrapure

- TriLobe Seal

- Pharma and Food

- Kalrez Sanitary Seals

- FDA Compliance

- Oil and Gas

- Kalrez News

Kalrez O-Rings and Seals

Kalrez Sanitary O-rings and Seals

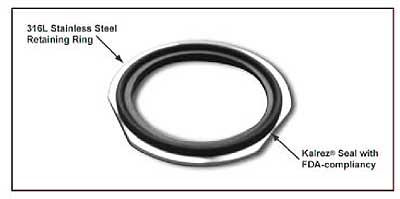

Stainless steel and Kalrez perfluoroelastomer parts combined in a controlled compression joint seal that provides premium performance.

Bioprocessing and pharmaceutical manufacturing processes must operate at the highest levels of cleanliness to assure product purity. Coupling joints in process lines can be a particularly troublesome source of contamination from various sources if the correct sealing material is not selected, as outlined in ASME’s BPEa-2000 Bioprocessing Equipment Standards. Substandard seal performance can also result in excessive process downtime and maintenance costs. Selecting the joint design and sealing material to provide the optimum balance of cleanliness and seal life is an ongoing challenge to the pharmaceutical process engineer.

DuPont is answering that challenge with the development of a new Kalrez Sanitary Seal design, a combination of two optimum performance engineering materials---stainless steel and Kalrez. Developed using Finite Element Analysis to simulate the range of temperatures a seal can see, this seal is designed with a metal retainer that controls compression of the seal and minimizes its intrusion into the process stream. The result is a prefabricated seal that provides the cleanliness of PTFE and the elastic memory of an elastomer while meeting stringent ASME requirements for joints intended for clean-in-place (CIP) and steam-in-place (SIP) applications. The Kalrez sealing element minimizes absorption, desorption and extractables to assure minimal contamination and a long sealing life.

Stainless Steel Retaining Ring

- Provides for controlled compression resulting in maximum seal life and reduced maintenance (eliminates the need to retorque)

- Rigid stainless steel ring helps maintain alignment during assembly

- Pry points to help with disassembly

Kalrez Seal

- Perfluorelastomer part provides the ultimate sealing performance for maximum efficiency with FDA compliancy

- Extractable levels comparable to PTFE

- Resistant to high operating temperatures (up to 260°C [500°F])

- Compatible with most pharmaceutical process media, including CIP and SIP

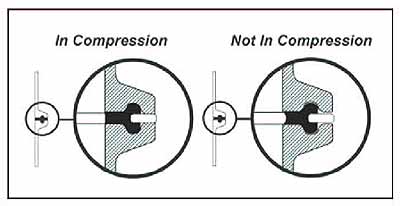

- Concave inside diameter is designed to minimize elastomer intrusion during process operations

Avoid These Common Coupling Problems By Specifying Kalrez Sanitary Seals

Intrusion from Overcompression---Too much sealing pressure can cause some elastomer seals to intrude into the process stream, resulting in product contamination. Overcompression can also result in seal splitting and loss of joint integrity.

Joint Leakage---Cold flow ("creep") of PTFE and some elastomers can cause loss of sealing pressure over time, requiring frequent inspections and retightening.

Seal Degradation---Incompatibility with fluids in the process line can cause some sealing materials to swell, crack and degrade, resulting in joint failure and process contamination. High process temperatures or repeated temperature cycling can also deteriorate seals made of many materials.

Sizes, Packaging and Availability

Kalrez Sanitary Seals are available in Compound 6230A (black) , supplied in individual bags and bar coded for full traceability. Sizes for 1/2, 3/4, 1, 11/2, 2, 21/2, 3, and 4 inch tri-clamp fittings are available and other sizes may be available as special orders.

CAUTION: Do not use in medical applications involving permanent implantation in the human body. For other medical applications, discuss with us.

The information set forth herein is furnished free of charge and is based on technical data that DuPont and Problem Solving Products, Inc. believe to be reliable. It is intended for use by persons having technical skill, at their own discretion and risk. Handling precaution information is given with the understanding that those using it will satisfy themselves that their particular conditions of use present no health or safety hazards. Since conditions of product use and disposal are outside of our control, we make no warranties, express or implied, and assume no liability in connection with any use of this information. As with any material, evaluation of any compound under end-use conditions prior to specification is essential. Nothing herein is to be taken as a license to operate or a recommendation to infringe on any patents. While the information presented here is accurate at the time of publication, specifications can change. Check with us before making a decision about which product to use.

DuPont™ and Kalrez® are trademarks or registered trademarks of E.I. du Pont de Nemours and Company or its affiliates. All rights reserved.