INJECTION

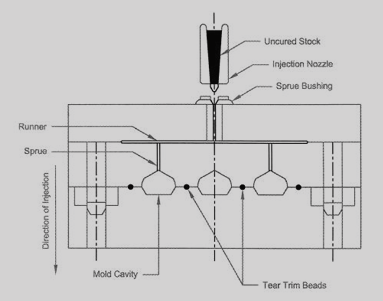

In the traditional “hot runner” process, the rubber compound, pre-heated in an injection cylinder, is then forced under pressure through an injection nozzle and into a system of sprues and runners, and finally culminates in the mold cavities. The system delivers the fastest production of finished products while it also creates significant waste material due to the scrap created by the runner system. However, this scrap can be minimized using a “cold runner” injection system, but at the expense of increased cure cycle times. Both the molds and the special equipment necessary to run them are very expensive, so it’s normally more cost effective for low volume jobs to employ compression or transfer molding methods.

COMPRESSION

Heavy compressive force and elevated temperatures form the material into shape.

More

TRANSFER

Preferred if the finished part involves complex geometry or demands tight tolerances.

More

INJECTION

The most efficient rubber molding process for rapid production of high volume, precision parts.

More