|

7108

S. Alton Way, Unit I |

(303) 758-2728

Home > O-ring, Seal Design > Considerations > Considerations 3

Gland Design

Special Considerations, Part 3

|

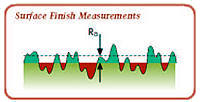

High-pressure applications may present unique challenges to elastomeric seals. Elastomers are essentially high-viscosity liquids - and as such will flow under extreme pressure conditions. In applications where the clearance gap is larger than that recommended for a traditional o-ring seal, the user should consider backup rings. These flat or contoured rigid rings are inserted on the low pressure side of the gland to prevent extrusion. Consideration of backup rings requires additional gland width to allow for elastomer expansion. In addition, chemical compatibility and ease of installation are other considerations when using backup rings. The surface finish of the gland can have a significant impact on the vacuum performance of seals. The following charts highlight terminology and processing techniques for specific surface finishes. Special care should be taken when sealing quartz components - not only due to the potentially irregular surface finish, but also to "light piping" effects on clear components in the sealing contact areas. Polymeric glands offer unique challenges if plastic deformation and creep of the sealing components are not taken into account. |

|

Surface

Finish Processes

Next Topic Semiconductor Plasma Environments and Elastomer Seals

We are located in the Denver Technological

Center in a suburb of Denver, Colorado

©1997-2017, Problem Solving Products, Inc.

Website Map | Privacy Statement

| Terms of Use