|

7108

S. Alton Way, Unit I |

(303) 758-2728

Home > O-ring, Seal Design > Semiconductor Plasma

Semiconductor Plasma Environments and Elastomer Seals

Semiconductor plasma environments offer significant challenges for elastomer seals. Specific chemistries for metal, oxide, poly etch and photoresist stripping equipment include the use of fluorine-, oxygen-, and chlorine-partially-ionized plasmas.

The plasmas typically used are called "glow-discharge," and they operate in the range of 10-4 to 10 Torr, with electron densities of 109 to 1012 cm-3, and ion temperatures of 0.03 to 0.04eV (100-200°C).

The function of a plasma is determined by: 1) the ability to deliver a uniform flux of energetic (+) ions to a surface with controllable energy and flux, and 2) the ability to deliver spatially uniform, relatively large fluxes of atoms and/or molecular radicals to surfaces. Three plasma properties that affect performance are:

- Chemical Reactivity-The partially ionized gas exhibits greater chemical reactivity.

- Ion Bombardment-Collision of ions and solid surfaces can generate vertical profiles and sputtering of material. Ion energies (100 -1000eV) transferred to the lattice atoms create a very short-lived cascade of moving atoms. If some of these atoms have enough energy to overcome the binding energy with the right path (trajectory) they form sputtered particles (atoms). (One atom/~500eV.) These moving lattice atoms can cause chemical reactions to occur.

- Electron Bombardment-Less important than the effects of energetic ions and chemically active radicals. Major effects are substrate heating and degradation of radiation-sensitive materials, e.g., plastics.

Traditional

measures of elastomer compatibility cover volume swell and physical

property degradation as a result of exposure to the gas. Plasma environments

offer many additional challenges for compatibility and contamination

performance of the elastomer.

Traditional

measures of elastomer compatibility cover volume swell and physical

property degradation as a result of exposure to the gas. Plasma environments

offer many additional challenges for compatibility and contamination

performance of the elastomer.

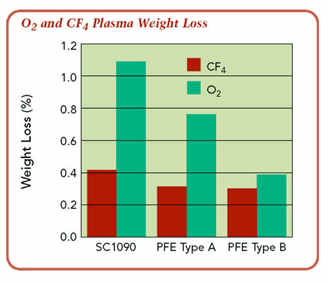

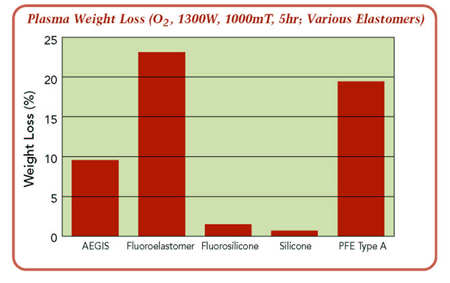

Measures of elastomer compatibility in plasma environments should include weight loss (including elastomer physical properties), and surface structural and chemical changes as measured by SEM/EDS and ESCA. With all the variables involved, testing of the elastomer in the actual application is recommended. CF4 O2 1.00E+0 9.

Next Topic Sealing in a Vacuum

We are located in the Denver Technological

Center in a suburb of Denver, Colorado

©1997-2017, Problem Solving Products, Inc.

Website Map | Privacy Statement

| Terms of Use