|

7108

S. Alton Way, Unit I |

(303) 758-2728

Home > Elastomer Properties > High Pressure

High Pressure Seal Performance

High Pressure Seal/Extrusion

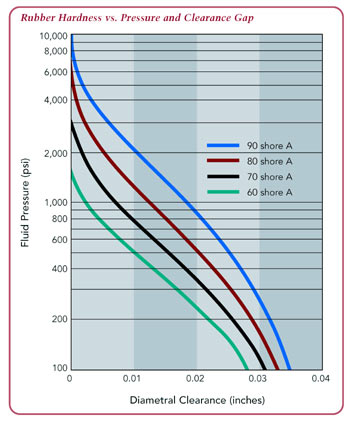

An elastomeric high pressure seal is typically designed to operate within ambient pressure to about 1,500 psi. At a very high pressure, the seal must have sufficient strength to resist extrusion into the clearance gap. The chart below illustrates the recommended limits of the combination of clearance gap (diametral), seal hardness, and pressure differential.

Techniques to avoid extrusion in a high pressure seal include decreasing the clearance gap, increasing the elastomer modulus (Mod 100) and the use of backup rings. Backup rings can be made of many rigid polymeric materials and are used on the low-pressure side within the gland to help prevent extrusion. Standard size backup rings are available for a high pressure seal in many materials.

Changes in Pressure/Vacuum

Cycling pressure can cause the high pressure seal to move back and forth within the gland. This can be especially damaging to a seal with poor dynamic properties or in applications with low compression, which will allow for more motion.

Next topic Vacuum Seal Performance

We are located in the Denver Technological

Center in a suburb of Denver, Colorado

©1997-2017, Problem Solving Products, Inc.

Website Map | Privacy Statement

| Terms of Use