|

7108

S. Alton Way, Unit I |

(303) 758-2728

Home > Elastomer Properties > Vacuum Performance

Vacuum Seal Performance

| Helium | Oxygen | Water | Nitrogen | |

| VMQ | 250 | 75–450 | 8,000 | 200 |

| FFKM | 60–80 | 6–8 | 90–100 | 8–12 |

| FKM | 9–22 | 1–2 | 40 | 0.05–0.7 |

| EPDM | 25–30 | 16-18 | – | 6–7 |

| FKM* *Highly fluorinated compound |

30 | 3 | – | 2 |

| (x10–8 sccm–cm/sec–cm2–atm) | ||||

In the semiconductor industry, many of the process steps are performed in a vacuum environment. Vacuum environments, even at levels of 10–9 Torr, often do not result in extrusion. The unique environment demands elastomer materials that have very low gas permeability and outgassing rates. The table shown lists a range of permeation rates for several types of elastomers.

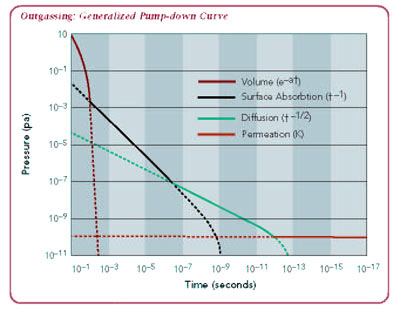

Gas release from vacuum components, referred to as outgassing, is a combination of volume, surface desorption, diffusion and permeation sources. The chart shown below is a generalized pump-down curve illustrating the contribution of these various sources in a high-vacuum system.

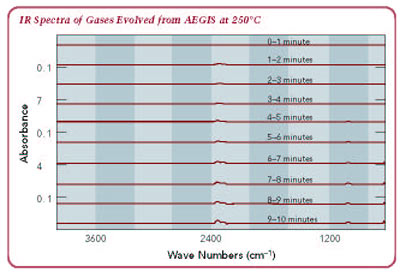

Analysis of outgassing components may be performed using a Residual Gas Analyzer (RGA). The mass spectra obtained during heating of AEGIS perfluoroelastomer is shown in the chart below. Water vapor (H2O), carbon monoxide (CO), and carbon dioxide (CO2) are released as the elastomer is heated. The decomposition temperature for fluoroelastomers is about 300°C. The decomposition temperature for AEGIS perfluoroelastomer is above 350°C.

Next topic Seal Thermal Stability

We are located in the Denver Technological

Center in a suburb of Denver, Colorado

©1997-2017, Problem Solving Products, Inc.

Website Map | Privacy Statement

| Terms of Use