|

7108

S. Alton Way, Unit I |

(303) 758-2728

Home > Elastomer Properties > Thermal Stability

Seal Thermal Stability

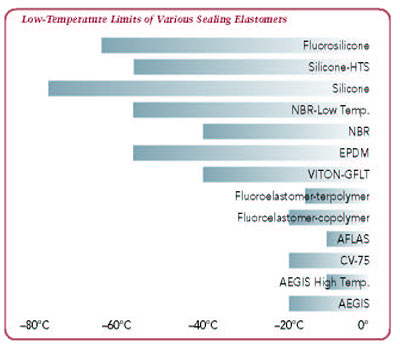

Low Temperature Seal Thermal Stability

The low-temperature limit is generally 15°F below TR-10 for static seals. For dynamic seals the TR-10 is more relevant. The TR-10 is the temperature at which an elastomer is able to retract 10%.

Low-temperature performance is generally a reversible process.

For design purposes compression is generally increased. The chemical media may cause swelling which may act as a plasticizer and lower the service temperature.

Definition of:

Glass Transition Temperature:

Thermal Expansion

| Material | Units | Therm. Stab. | x10–5 /°C |

x10–6 /°F |

| FKM | 200°C | 16 | 90 | |

| NBR | 120°C | 23 | 62 | |

| VMQ | 230°C | 59–79 | 103 | |

| FFKM | 300°C | 23 | ||

| EPDM | 150°C | 16 | ||

| Stainless | – | 1.04 | ||

| Aluminum | – | 1.3 | ||

| TFE and FEP | 230°C | 5–8 | ||

| KEL-F | 280°C | 4–7 | ||

| Polyimide | 275°C | 5 |

| Thermal

Conductivity (g-cal/sec/cm2/cm/C) |

Specific

Heat (cal/g/C) |

|

| VMQ | 0.330–0.515 x 10–3 | 0.28–0.35 |

| SC1030/SC1020 | 0.6/0.8 x 10–3 | 0.2 |

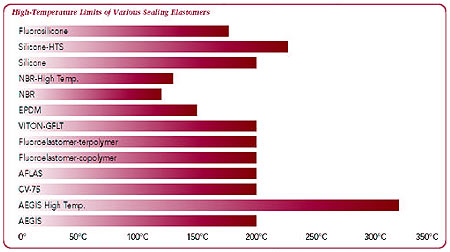

High Temperature Seal Thermal Stability

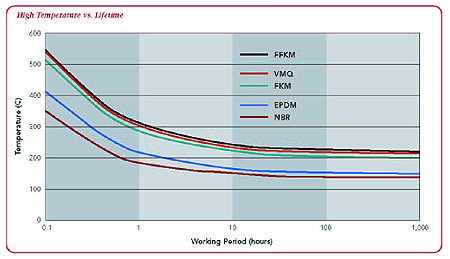

The high-temperature limit for seal thermal stability is generally considered a 30–50% loss of physical properties and typically represents a maximum temperature for 1,000 hours continuous service. It represents an irreversible change in the backbone or cross-link network.

The effect of high temperature can be compounded by the interaction with the chemical media. Chemical reactions typically double with a 10°C increase in temperature.

Definition of:

- Thermal Conductivity: ASTM C177, C518

- Thermal Expansion: ASTM D864

- Heat Aging: ISO 188, ASTM D454, D572, D573, D865

Viton® was a registered trademark of DuPont at the time the article was written and is now a registered trademark of the Chemours Company.

Next topic Chemical Seal: Chemical Compatibility

We are located in the Denver Technological

Center in a suburb of Denver, Colorado

©1997-2017, Problem Solving Products, Inc.

Website Map | Privacy Statement

| Terms of Use