|

7108

S. Alton Way, Unit I |

(303) 758-2728

Home > Elastomer Properties > Physics

The Physics of Rubber

Rubber is composed of long chains of randomly oriented molecules. These long chains are subject to entanglement and cross-linking. The entanglement has a significant impact on the viscoelastic properties such as stress relaxation. When a rubber is exposed to stress or strain energy, internal rearrangements such as rotation and extension of the polymer chains occur. These changes occur as a function of the energy applied and the duration and rate of application, as well as the temperature at which the energy is applied.

A rubber’s response to an applied energy can be energy storage (elastic) or energy dissipation (viscous). For sealing elastomers, the elastic component of response is most important. An applied stress induces a corresponding strain which creates contact stress (or sealing force). As the polymer chains rearrange to reduce this internal energy, or stored force, a loss of sealing force occurs.

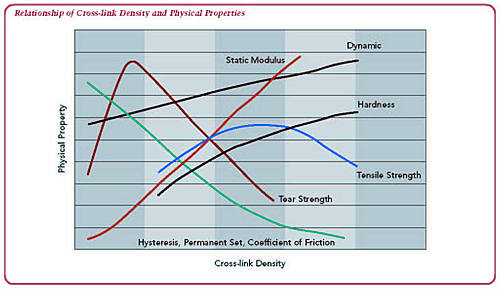

Rubber products are typically cured at high temperature and pressure. The addition of curatives and accelerators forms cross-links between the polymer chains or backbone. It is this network of cross-links that largely determines the physical properties of tensile, elongation and compression set.

Fillers play a large role in rubber technology. Carbon black and silica fillers can serve to improve the hardness, abrasion resistance, tensile properties and tear strength. Non-black fillers, such as titanium dioxide and barium sulfate can offer pigmenting properties for part identification, as well as improved stability in strong oxidizing environments. However, the viscoelastic response and hysteresis losses are greatly enhanced by the use of fillers.

The physical properties of an elastomer vary with the test conditions—especially temperature. The rate of application of a load also has an effect, as does previous stress history.

Next topic Elastomer Properties - Hardness

We are located in the Denver Technological

Center in a suburb of Denver, Colorado

©1997-2017, Problem Solving Products, Inc.

Website Map | Privacy Statement

| Terms of Use