|

7108

S. Alton Way, Unit I |

(303) 758-2728

Home > Elastomer Properties > Compression Set

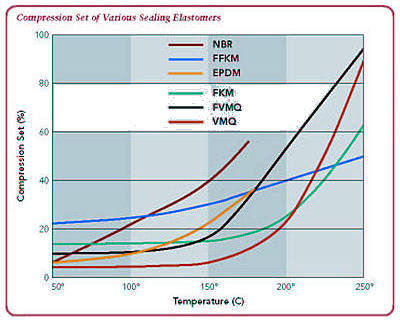

Elastomer Properties - Compression Set/Creep

Elastomer

compression set is a measurement of the ratio of elastic to viscous

components of an elastomer’s response to a given deformation.

Longer polymer chains tend to give better “set resistance”

because of the improved ability to store energy (elasticity).

Elastomer

compression set is a measurement of the ratio of elastic to viscous

components of an elastomer’s response to a given deformation.

Longer polymer chains tend to give better “set resistance”

because of the improved ability to store energy (elasticity).

Elastomer compression set measurement standards call for a 25% compression for a given time and temperature. The cross-section is measured after the load is removed. Elastomer compression set is the percentage of the original compression (25%) that is not recovered. This test may be conducted on cylindrical disks or O-rings. At the end of the test, the samples are removed and allowed to cool at room temperature for 30 minutes before measuring. After a load is released from an elastomer, the difference between the final dimensions and the original dimensions is considered the compression set.

The use of elastomer compression set measurements is most beneficial for production quality control, indicating the degree of curing. Elastomers with high compression set values may require special considerations for gland design and handling. Elastomer compression set is a relatively simple test to perform, and as such, may not yield the type of predictive information desired for custom sealing applications.

When a constant load is placed on an elastomer, the deformation is not constant, but rather it increases gradually with time. Terms used to describe this behavior are relaxation or creep. These properties, including compression set, are a result of physical (viscoelastic) and chemical (molecular structure) changes in an elastomer.

Test Methods:

-

ISO 815 (Ambient & High Temp.)

-

ISO 1653 (Low Temp.)

-

ASTM D395 (Ambient & High Temp.)

-

D1229 (Low Temp.)

Next topic Elastomer Properties - Stress Relaxation/Retained Sealing Force

We are located in the Denver Technological

Center in a suburb of Denver, Colorado

©1997-2017, Problem Solving Products, Inc.

Website Map | Privacy Statement

| Terms of Use