|

7108

S. Alton Way, Unit I |

(303) 758-2728

Home > Kalrez® News 2 > Article 9

Kalrez® News 2 - Article 9

GE Switches To Kalrez® Perfluoroelastomer Parts To Reduce Downtime And Maintenance Costs

Talk to Problem Solving Products about purchasing Kalrez® o-rings and seals. |

News Release from DuPont (formerly named Dupont Performance Elastomers when this article was written)6/19/2008 |

GE Power Protection of Gent, Belgium, a division of GE Consumer and Industrial, has dramatically reduced downtime, enhanced the reliability of its key compression molding processes and cut seal costs by at least €21 000 per year by switching to DuPont Performance Elastomers (DPE) Kalrez® Spectrum™ 6375 perfluoroelastomer parts. The same Kalrez® O-rings are still functioning well since installation in 2005.

GE Power Protection is a leading manufacturer of electrical components, enclosures and switchboards for industrial process automation. Its innovative compression-molding production line uses steam at up to 165°C to heat the stamping-press. Steam at this temperature can be aggressive to some other elastomers, and can cause embrittlement, surface cracking and reduction in tensile strength - resulting in significant loss of sealing force. However, Kalrez® Spectrum™ 6375 perfluoroelastomer parts provide continuous service in temperatures up to 275°C, and may lead to longer seal life, as in the GE Power Protection application.

"No More Standstills"

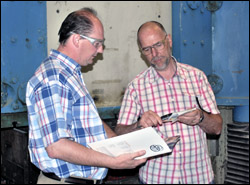

Erik Buysse (right), project leader Toolshop, and Danny Pattijn, shop floor manager Toolshop – GE Power Protection, examine a Kalrez® Spectrum™ 6375 perfluoroelastomer O-ring that has enabled the company to dramatically reduce downtime, enhance the reliability of its key compression molding processes, and cut seal costs by at least €21 000 per year. |

"We were replacing the original O-rings about every six months because of the incompatibility of the FKM with hot steam. Production had to be stopped for at least two days each time the seals leaked - incurring very high maintenance costs due to the enormous dimensions of the mold. We also had the problem that every unexpected stop affected production planning and delivery schedules," said Erik Buysse, project leader Toolshop - GE Power Protection.

"Realizing that elastomer performance was a critical component in improving seal lifetime, we installed a pilot Kalrez® SpectrumTM 6375 O-ring in September 2005, which is still functioning well. As a result, we have had no more standstills to replace O-rings - gaining time, increasing yields, reducing maintenance and saving an estimated €21 664 per year in seal costs."

"Since the Kalrez® O-rings have also led to greater reliability and a five times increase in Mean Time Between Repair (MTBR), we have decided to upgrade all critical O-rings to Kalrez® SpectrumTM 6375 parts," Buysse confirmed.

Estimated Savings

The life cycle cost savings estimated by GE Power Controls were made using DPE’s online value-in-use calculator tool, available at www.dupontelastomers.com/products/kalrez/optimize.asp

About Kalrez® SpectrumTM 6375

Kalrez® SpectrumTM 6375 perfluoroelastomer parts are manufactured by DPE to meet the needs of the chemical processing industry. They provide outstanding performance in a broad range of chemicals including acids, bases, amines and steam, and provide continuous service in temperatures up to 275°C, in applications such as mechanicals seals, valves, flanges and pumps, where elastomeric sealing is critical.

About DuPont Performance Elastomers

DuPont Performance Elastomers (DPE), a global supplier of specialty elastomers with headquarters in Wilmington, Del., USA, is a wholly owned subsidiary of DuPont. The company is an industry leader in chloroelastomers and fluorinated elastomers, serving the automotive, chemical, petrochemical, semiconductor, food and pharmaceutical processing, construction, general rubber and wire and cable industries. In addition to Viton®, DPE’s current offering includes Neoprene synthetic rubber, Hypalon® chlorosulfonated polyethylene, Kalrez® perfluoroelastomer parts and Vamac® ethylene acrylic elastomers.

About GE Power Protection

GE Power Protection employs about 600 people at its 130 000 m2 facility in Gent, Belgium. The company manufactures electrical equipment and components for residential and industrial low voltage distribution, automation and controls, enclosures and switchboards. Its products are designed for electrical and engineering contractors for the process industry, telecom and infrastructure markets.

We are located in the Denver Technological

Center in a suburb of Denver, Colorado

©1997-2017, Problem Solving Products, Inc.

Website Map | Privacy Statement

| Terms of Use